Carbon Recycle has specially designed and manufactured a "2000Nm 3/h dichloromethane recovery system" for this project, taking into account the on-site production conditions of users and the properties of volatile gases.

The system adopts a combined recovery and treatment technology of "compression condensation gas separation membrane resin activated carbon adsorption". After this process, organic gases in the volatile gas can be recovered to a large extent; Meanwhile, after adsorption by resin and activated carbon, the outlet concentration of organic gas is ≤ 30mg/m 3.

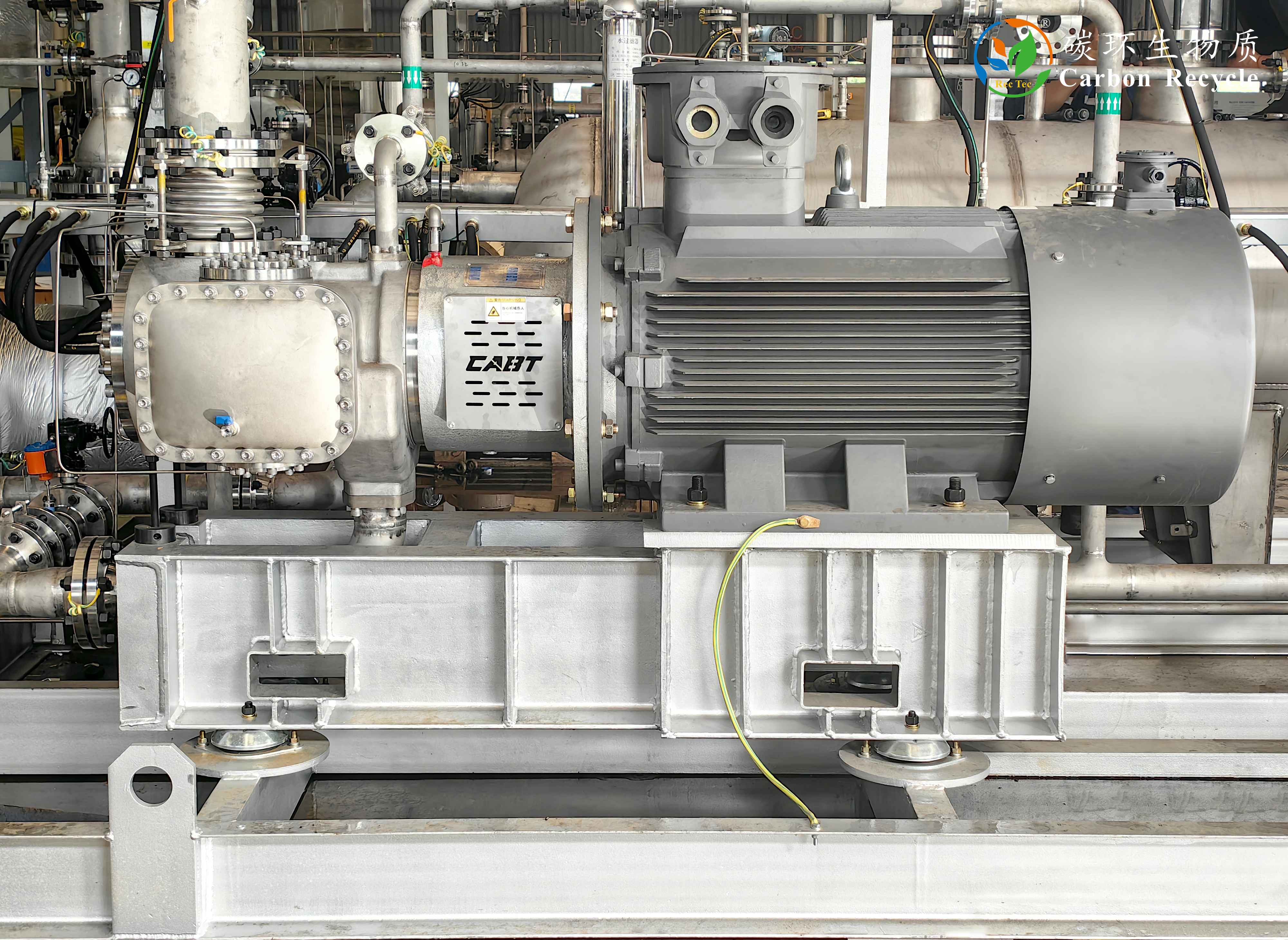

The oil-free single screw compressor selected for the compression unit adopts advanced WX-II type line, and the volumetric efficiency (Max) of the head is ≥ 95%. The metal components such as the shell, rotor, bearing seat, cover plate, and fastening bolts that come into contact with the medium are all made of 316L stainless steel material. The screw and star wheel are processed using SINUMERIK CNC machining software, manufactured by a five axis linkage machining center, and the shell is processed by a horizontal machining center. And use a coordinate measuring instrument for form and position tolerance detection to ensure machining accuracy. The contour of the screw surface is ± 0.01mm, the roughness is less than Ra0.4, and the imbalance of the screw and star wheel is better than G1 grade. The meshing pair of the compressor has high machining accuracy, low wear, low vibration, and low noise.

The gas separation membrane is a polymer organic gas separation membrane composed of a three-layer structure, namely a base layer, a support layer, and a dense layer. The combination strength between the support layer and the functional layer is high, and the service life is long.

The resin adsorption system adopts a three tower mode and uses efficient resins with large desorption capacity, good selective adsorption, and easy desorption. It has a good mesh structure and a high specific surface area, which can selectively adsorb organic molecules through pore size screening, intermolecular forces, or hydrogen bonding. It is applied for the adsorption and recovery of volatile organic compounds (VOCs) at medium and low concentrations, achieving standard emissions.

The activated carbon adsorption system adopts a two tower mode, and the selected activated carbon has strong adsorption capacity. Activated carbon has a large surface area, high adsorption efficiency, and can also save energy consumption to a large extent.

At present, the VOCs waste gas recovery and treatment device designed and manufactured by Carbon Recycle has been widely used in industries such as pharmaceuticals, fine chemicals, petrochemicals, new energy, and new materials, achieving source recovery and resource utilization of organic waste gas, reducing product energy consumption and operating costs, significantly reducing the load and operating costs of enterprise end incineration systems, and meeting high emission standards and requirements.